Awards & Grants

Closing the loop in battery manufacturing

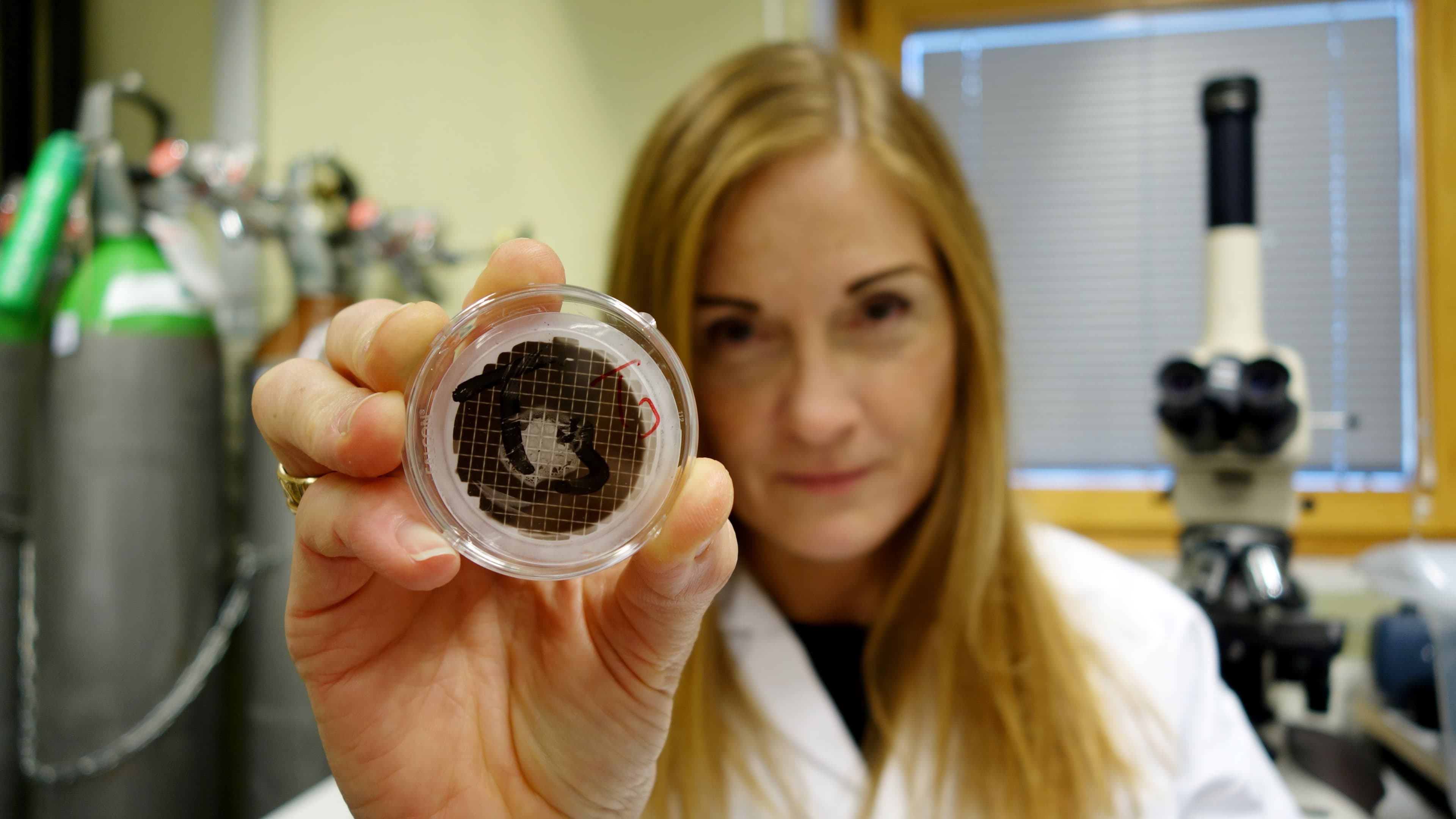

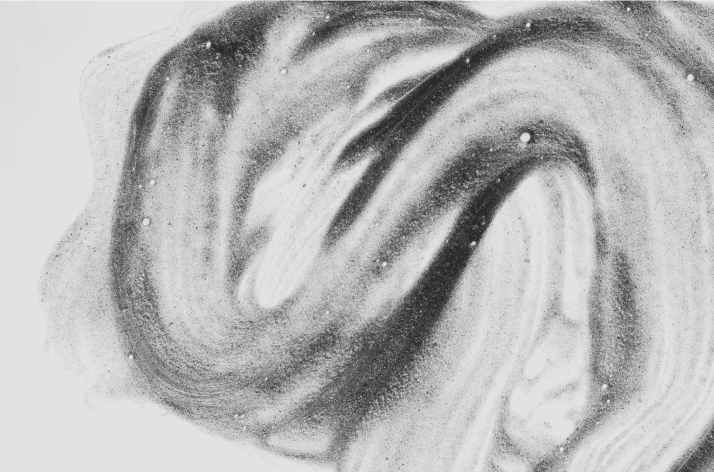

Black dust hinders production and endangers staff. But when properly managed, it can be highly valuable. At DREV, we've developed tools and services that enable manufacturers to safely capture, recycle, and reuse these particles, transforming waste into a resource.

Turn Microparticle “Waste” Into Valuable Resources

Turn black dust into precious metal

Powered by patent-pending dry brush technology and a revolutionary canister, our Vault products eliminate water and harsh chemicals from the decontamination process and enable the adaptive reuse of precious materials.

Vault

StationaryConstant, controlled particle collection at all levels of battery manufacturing. Learn more

Vault

AutonomousReduce the need for human intervention in restricted and highly contaminated areas. Learn more

Partners

8.5

TWhGrowing consumption

By 2030, the global battery production capacity will exceed 8.5TWh, enough to power over 4M electric vehicles for one year.

200

k m2Growing footprint

Today’s gigafactories regularly exceed 200k ㎡ of dry and clean room space—greater than the average 18-hole golf course.

Cleaning for tomorrow’s factory. Not yesterday’s.

Existing decontamination tools slow production, squander precious materials, and endanger staff. At DREV, we’re working to set a new standard.

About us

We’re on a mission to revolutionize how industrial spaces maintain cleanliness and efficiency. Learn more

Our team

We bring years of experience from places like Panasonic Energy of North America and PowerCell. Learn more about us.

Insights

Read our blog to get the latest thoughts from our team. DREV Insights